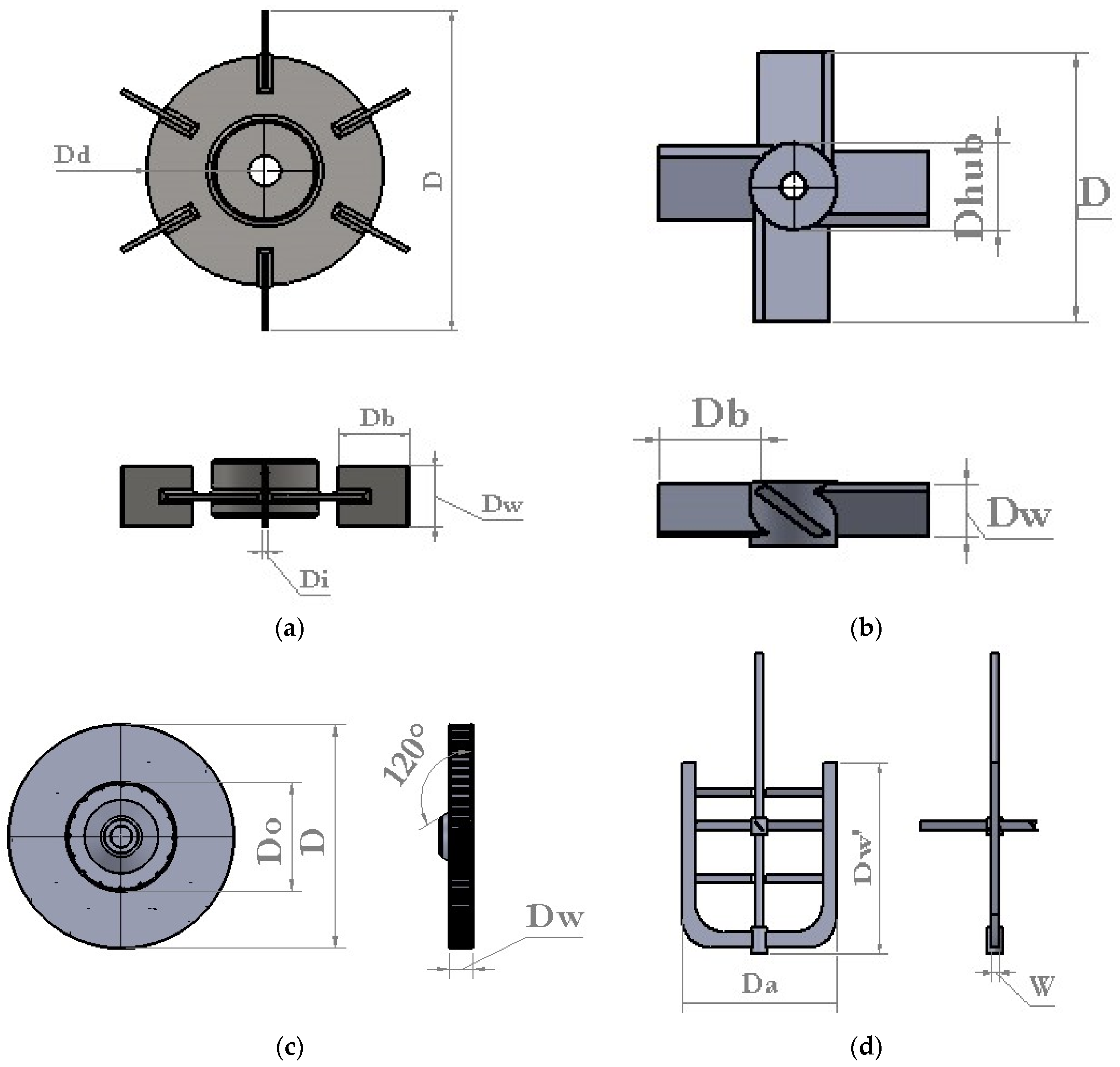

Each product exported to one of these countries is supplied with a technical passport and IOM manual in Russian. suitable for export to all member states of the East Asian Community Russia, Belarus, Kazakhstan, Armenia and Kyrgyzstan (TR CU 010, TR CU 012, ambient temperature -49/+40☌). Anchor Agitators : This simple agitator consists of a shaft and an anchor type propeller and can be mounted centrally or at an angle. The complete range is also TR CU certified and EAC marked, i.e. I am asking this because on low level alarm (20 ) of tank, agitator is not getting immersed in liquid resulting in frequent damage to bearing due to vibration so we have changed alarm value to 50 instead of 20. Below are the inputs required and my considerations: Inner dia of reactor: 1.82 m, Sweep dia / Agitator dia : 1.6 m, Agitator Speed: 60, Motor RPM, Mr : 1475, Reaction mass density : 1500 Kg/m3, Reaction mass viscosity : 1. Design Of Shaft Length Of Agitator - posted in Industrial Professionals: Agitator shaft length should be calculated on which basis. Roberto Voltan.Īll PRO-DO-MIX ® agitators can be produced in accordance with Directive 2014/34/EU-ATEX for installation in hazardous environments (Potentially Explosive Atmosphere). Lets try our case with a 5 KL SS reactor with Anchor agitator. The technical brochure is availabe at our site: the person authorized to compile the technical file is Mr. Turbine agitators are very versatile they are able to handle a wide variety of mixing operations because these agitators can create turbulent movement of the fluid. These agitators have an axial input and the output is radial. Our agitators are suitable for any type of fluid, even with very high density, up to 2.5 kg/m 3 avoiding sedimentation, improving heat exchange and helping chemical reactions.Īll PRO-DO-MIX ® agitators are CE marked and this logo is branded on each machine. Anchor Agitators Propeller Agitators Helical Agitators 1.

Some of these, such as the gate-anchor agitator can be used with high. Lid can be fitted with temperature probe, cleaning spray nozzles, vacuum fittings, light and sight glass, flanges and multiple product inlet nozzles for delivery of liquid raw materials. The design of agitator product contact parts should minimize the occurrence of.Figure 6: Velocity vector at the tip of turbine impeller blade. Wetted parts are stainless steel polished to 120-grit for ease of cleaning (#4-8 Mirror finish is available upon request). Anchor impeller provides good agitation near.

#Anchor agitator design full

ASME code stamped Vessel can be designed for full vacuum/100-psig service with 150-psig dimpled, Half- Pipe, conventional stainless-steel jacket is supplied around the vessel for heating/cooling (High pressure rating is available upon request).anchorandhelical ribbon agitators werecarried out. Helical Blade Low Speed Agitator with Offset rotating baffle. Anewpower correlation for both anchor and helical ribbon impellers in highly.

0 kommentar(er)

0 kommentar(er)